Flexible, dry self-priming, and easy to repair: the impeller pump

ZUWA impeller pumps are particularly easy to maintain and inexpensive to operate. Thanks to their flexible impellers, they are insensitive to solid particles in the medium and can even pump highly viscous liquids.

The different materials used for the components (pump housing and flexible impeller) and the possible drive options result in an extensive range of pumps. This system makes our impeller pumps suitable for almost every conceivable application. Our in-house production and workshop enable us to fulfill special requests, produce custom-made products, and carry out repairs at any time.

We offer housings made of aluminum, stainless steel, and plastic. The replaceable impeller wheel is available in the following materials: NBR, EPDM, CR, FKM, FPM, and TPU.

Our flexible impeller pumps can be used with various drives: with electric motors, compressed air motors, V-belt drives, hydraulic motors, with a drill, or with a cordless screwdriver using an adapter.

Pump types

UNISTAR

The universal pump for pumping clean or contaminated liquids without abrasive substances (for media that are non-abrasive and non-corrosive).

- Flow rate up to 120 l/min

- Delivery pressure up to 5 bar

COMBISTAR

The pump for all liquids that may contain abrasive substances. The affordable alternative to the NIROSTAR series. Perfectly suited for pumping abrasive or slightly corrosive media.

- Flow rate up to 60 l/min

- Delivery pressure up to 5 bar

NIROSTAR

High-quality stainless steel pump with a wide range of applications in industry and plant engineering, perfectly suited for corrosive media.

- Flow rate up to 730 l/min

- Delivery pressure up to 5 bar

ACOSTAR

PTFE impeller pump for chemical applications. It is perfectly suited for various process media as well as a wide range of acids, alkalis, viscous liquids, and solvents.

- Flow rate up to 28 l/min

- Delivery pressure up to 3 bar

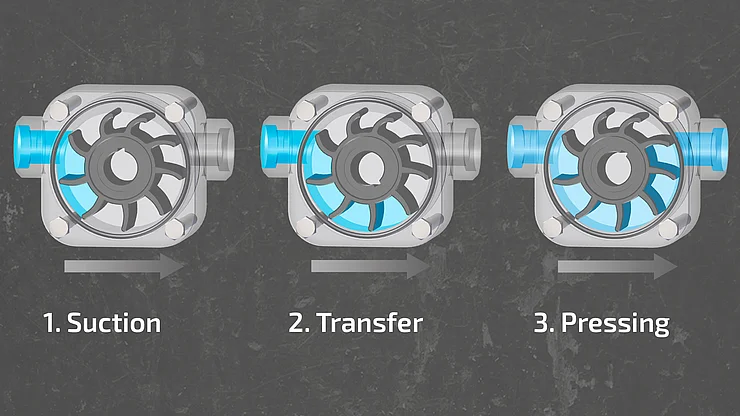

Functional principle of the impeller pump

1. Suction

On the suction side the blades begin to straighten. The chamber space between each blades enlarges and creates a vacuum pulling the fluid into the pump.

2. Transfer

With the turning of the impeller the fluid is positively displaced from the inlet to the outlet. Small particles are also able to be pumped freely through the chambers.

3. Pressing

On the pressure side the blades of the impeller begin to flex causing the chambers to shrink, therefore forcing the fluid in a constant flow out of the pump.

Advantages

Dry self-priming

A major advantage of the impeller pump is that it does not need to be filled before commissioning. The pumps are dry self-priming up to a depth of 3 meters. With a filled suction line, the maximum suction depth is 7 meters.

Powerful

The flow rate of ZUWA impeller pumps ranges from 3 to 730 liters per minute. Containers can be emptied almost to the last drop.

Versatile

Suitable for a wide range of liquids and applications. The materials used for the impeller, seal, and pump housing can be adapted to suit the area of application and requirements. Motors with alternating current, direct current, and three-phase current are available in various speeds.

Reliable

All pumps are tested in continuous operation in our workshop. High-quality materials guarantee a long service life.

Easy to maintain

Assembly/disassembly of the housing and replacement of the impeller is quick and easy.

Spare parts are available individually. Low operating costs!

Robust

Impeller pumps can also pump highly viscous liquids such as oil or honey (up to 20,000 mPas), as well as liquids containing solids. The maximum permissible liquid temperature is 90 °C. Dry running for up to one minute is tolerated.

Gentle

The conveying is pulsation-free. Small amounts of air can be conveyed along with the fluid.

Area of Application

- Maritime

- Biotechnology

- Heating and sanitation

- Electroplating and workshops

- Agriculture and gardening

- Water and wastewater treatment

- Beverage and food industry

- Industry, mechanical engineering, and plant construction

- Chemical, pharmaceutical, and cosmetics industry