Diaphragm pumps – Versatile technology for different liquids

Diaphragm pumps are robust, reliable positive displacement pumps that have been specially developed for pumping a wide variety of liquids. They operate gently, are self-priming, and are safe to run dry—making them ideal for many applications in agriculture, workshops, and industry.

Our range of diaphragm pumps is designed for:

- Plant protection products

- Oils and lubricants

- Diesel fuel

- Kerosene

- Water

- AdBlue®

- Antifreeze

- Windscreen washer fluid

Whether you are looking for a solution for agricultural spraying technology, workshop use, or industrial dosing, we offer the right diaphragm pump for your application.

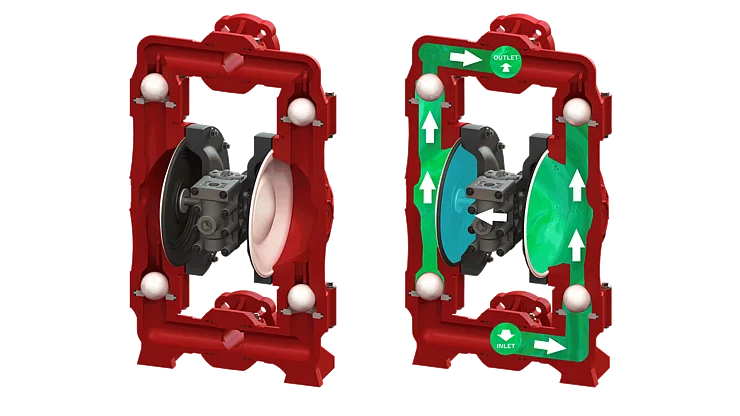

How a diaphragm pump works

Diaphragm pumps belong to the group of positive displacement pumps and operate with a flexible diaphragm that sucks in and conveys fluid through mechanical movement. The function is based on a simple but very effective principle:

suction stroke:

The diaphragm is pulled backward (e.g., via an eccentric shaft or a pneumatic drive). This creates negative pressure in the pump housing, which draws the liquid into the pump chamber through an inlet valve.- pressure stroke:

The diaphragm is then pushed back to its original position. The pressure generated closes the inlet valve and simultaneously opens the outlet valve. This forces the liquid out of the pump.

This cycle repeats continuously and ensures a steady flow rate. The valves (usually ball valves or flaps) reliably prevent the fluid from flowing back.

Advantages of the diaphragm pump principle:

- Self-priming (even with dry pipes)

- Dry-run safe – no damage during short-term operation without medium

- Suitable for aggressive or sensitive media

- Low maintenance – no rotating seals in the medium

- High chemical resistance (depending on material selection)

Overview of the models

MC-Series

The robust double piston diaphragm pumps are versatile and can be used in agriculture and cleaning applications. They deliver liquids evenly in the medium pressure range and have good suction properties. They are mainly used for applying pesticides to small to medium-sized areas, as well as for disinfecting stables and cleaning PV and industrial systems.

A special corrosion-resistant version with a propylene housing and Viton® diaphragms is available for use with acids. The pumps can be flexibly mounted on various vehicles.

AdBlue® diaphragm pump

AdBlue® is used to reduce nitrogen oxide emissions in modern diesel engines and requires material-resistant conveyor technology.

Our diaphragm pump without dynamic seals is particularly low-maintenance and reliable.

The pump head made of technopolymers makes it ideal for AdBlue®, antifreeze, and water. The pump is ideal for transferring and filling from drums, IBCs, or tanks and ensures a clean and safe pumping process.

- Grommet for ¾" hose connector

- No dynamic seals

- 2 m cable with plug (available in 230, 12, and 24 V)

- DC pump with handle available

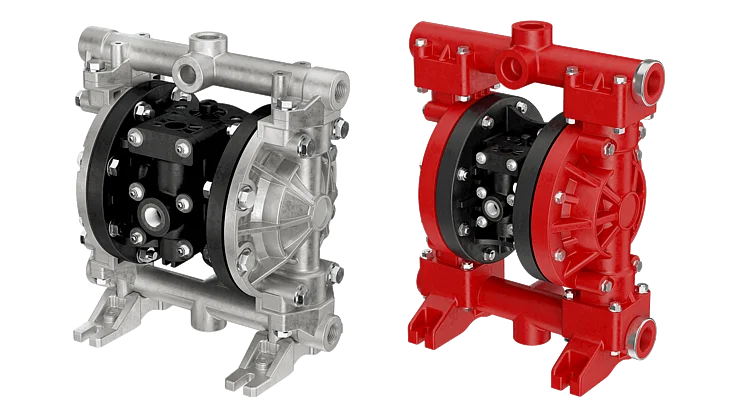

MA / MP-Serie

The redesigned compressed air diaphragm pumps feature an innovative air distribution design that makes maintenance and repair particularly easy. The integrated anti-stall system ensures uninterrupted operation—with reduced air consumption and significantly lower noise levels.

The housing is made of high-performance, reinforced technical polymer. This material guarantees maximum resistance to aggressive media and an exceptionally long service life—ideal for reliable use in demanding industrial environments.

MP-Version

Suitable for:

- AdBlue®

- Water

- Antifreeze

- Windscreen washer fluid

MA-Version

Suitable for:

- Oil with a viscosity range

of 1-50,000 cps at 20 °C - Diesel

- Kerosene