We can offer various pump types for oils:

- Vane pumps (Viscomat)

- Up to 50 l/min, up to 6 bar

- Wide selection of AC and DC pumps

- Some models equipped with bypass valve

- Gear pumps (Viscomat, Viscomat Gerotor, Viscostar)

- Up to 70 l/min, up to 20 bar

- High temperatures up to 230°C possible

- teilweise mit Bypassventil ausgestattet

- Impeller pumps (UNISTAR)

- Up to 90 l/min, up to 5 bar

- Bidirectional operation possible

- Very good suction properties

- Solids can be conveyed along with the fluid

Model series at a glance

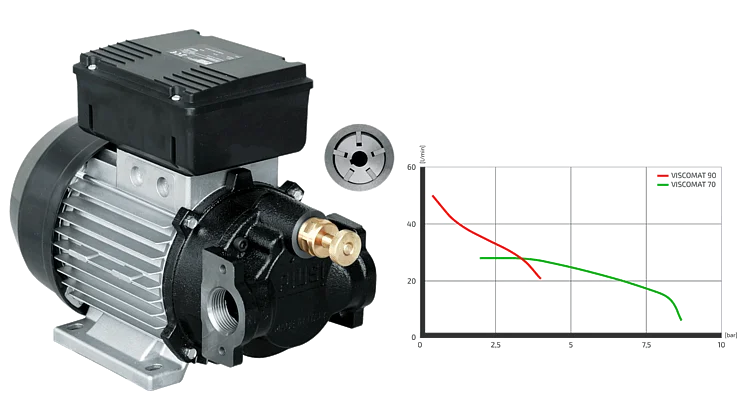

Viscomat vane pumps (70/90)

Viscomat 70 | 90 for oils

Vane pumps from the Viscomat series are suitable for clean oils with a viscosity of up to 500 cSt (e.g., heating oil, vegetable oil, motor oil) with a maximum media temperature of 60 °C.

Flow rate: 25–50 l/min at 1,450 rpm

Delivery pressure: up to 6 bar

- Specially designed blades for oils

- Low-noise operation (<70 dB)

- Delivery head: up to 4 m with foot valve

- Integrated flow valve for volume control (except VISCOMAT 90-m)

Viscomat gear pumps (200/230/350)

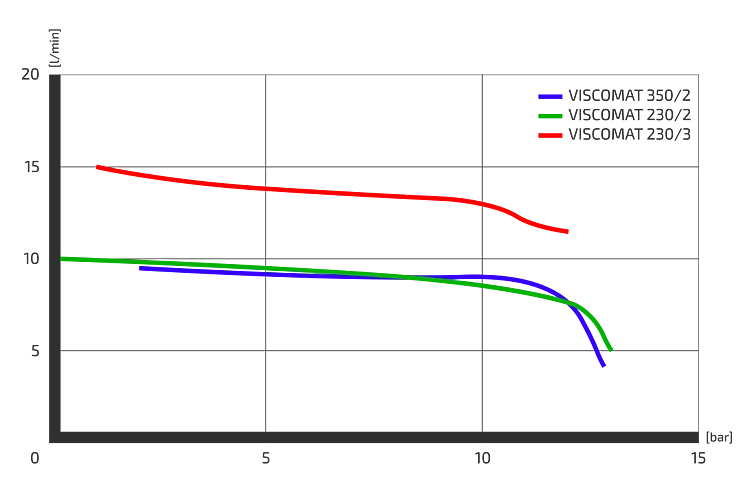

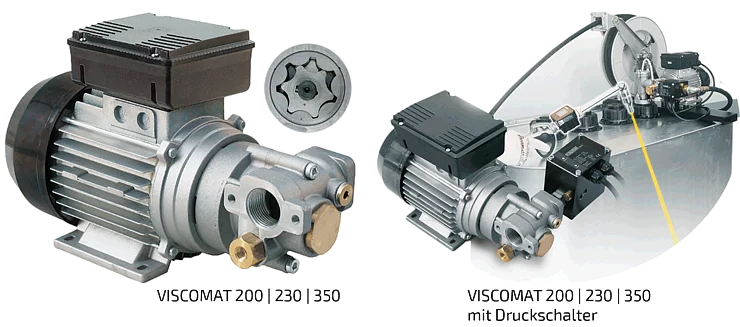

Viscomat gear pumps 200 | 230 | 350

Viscomat gear pumps offer reliable pumping solutions for viscous liquids such as oils and lubricants. With their robust design and high efficiency, they are ideal for industrial applications that require precise dosing and consistent flow rates.

Performance data for Viscomat gear pumps:

- Flow rate: Up to 14 l/min (depending on model)

- Max. pressure: Up to 25 bar

- Max. temperature: Up to +60 °C,

- Cast iron housing, sintered steel gears

- Viscosity: Suitable for media up to 2000 cSt

Engine options:

Available with 230 V, 400 V, 12 V, and 24 V motors

All models with a 230 V motor are also available with a pressure switch for automatic switching on/off when the nozzle is activated.

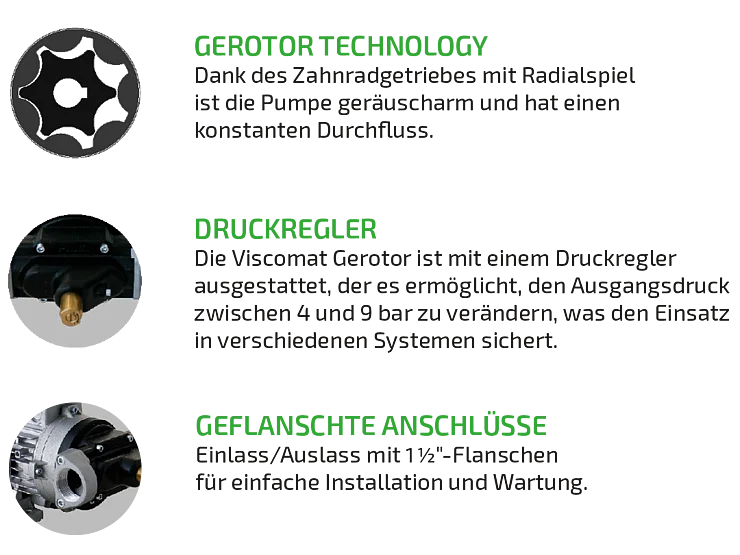

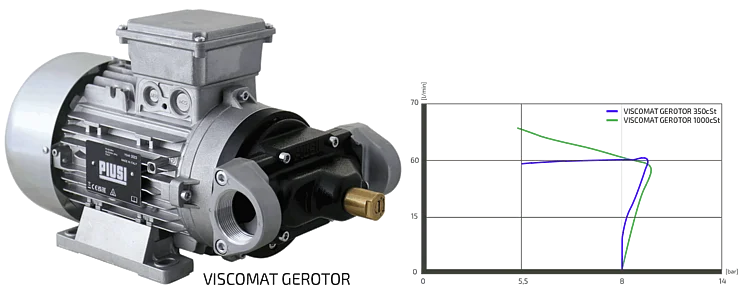

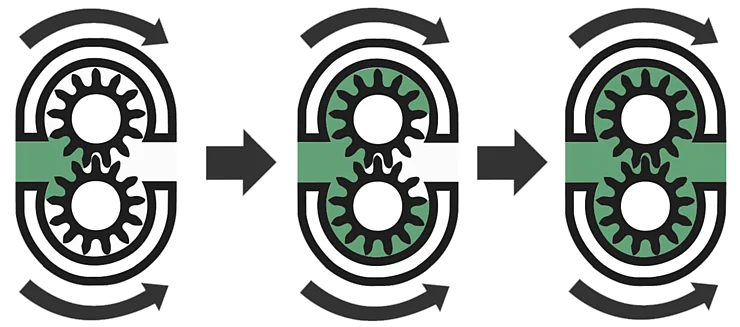

Viscomat GEROTOR

Viscomat Gerotor: Efficient conveyor technology for oils and lubricants

The Gerotor pump uses reliable Gerotor technology to deliver oils and lubricants evenly and efficiently. With its robust design and a delivery rate of up to 70 l/min, it ensures a constant, pulsation-free flow of fluid – ideal for use in gas stations, workshops, and industrial facilities.

Advantages:

- High flow rate up to 70 l/min

- For oils with a maximum viscosity of 1000 cSt

- Max. temperature +100 °C

- Cast iron housing, steel gears

- Low wear and easy maintenance

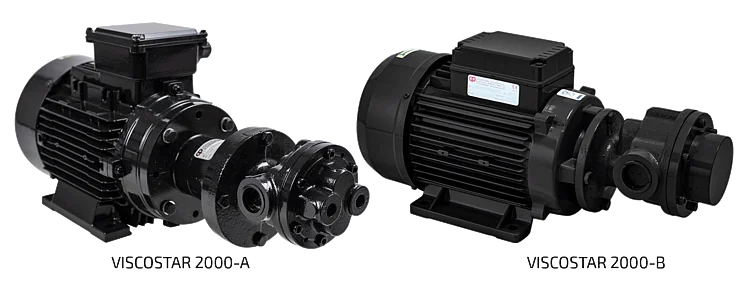

Viscostar-Series (Typ A-F)

VISCOSTAR: Gear pumps for the most demanding requirements

Our Viscostar gear pumps are specially designed for use with low to high viscosity and particle-free oils and lubricants up to 4000 cSt. High operating temperatures of up to +230 °C are possible, making them ideal for use in demanding processes where other types of pumps would reach their limits.

For a long service life, the housing and cover are made of GG-25 gray cast iron, and the shafts and gears are made of hardened case-hardened steel.

Other advantages include:

- Low shear effect

- High pressures possible

- Suitable for high viscosity

- Consistent flow rate

- Very good suction line

Versatile areas of application

- Low- to high-viscosity, particle-free liquids

- Liquids with good lubricating properties

- Light and heavy oils

(e.g., emulsions, diesel, lubricating oil, thermal oil, hydraulic oil, or vegetable oil) Versatile areas of application

Impeller pump

Impeller Pump Unistar

The dry self-priming impeller pumps can empty barrels down to the last drop. Thanks to their flexible impeller, the pumps are insensitive to solids in the medium and are therefore particularly suitable for pumping waste oils and contaminated fuels.

- Extracting waste oil from engines and gearboxes

- Extracting cooling lubricants

- Maintaining machines

- Emptying heating oil and diesel tanks

- Optional dry-running protection