Henry Ford once said: "If you always do what you've always done, you'll always get what you've always got."

That's why we at ZUWA work on our products every day – improving, modifying, and adapting them to the requirements of our customers. We would like to take this opportunity to inform you about some innovations we have recently implemented in some of our well-known products.

IMPROVED IMPELLER DESIGN THROUGH CHAMFERED BLADES

The new design of our flexible impeller wheels reduces frictional resistance and the resulting frictional heat in the pump housing. The chamfered impeller blades delay the onset of possible dry running and increase the service life of the impeller, especially in slurping operation. To completely prevent dry running, we recommend using dry run protection for our impeller pumps.

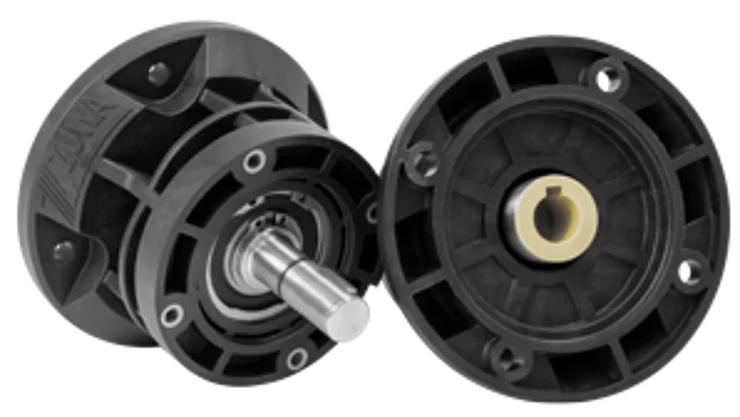

PUMP MOUNT WITH NEW SHAFT BEARING AND SHAFT BUSHING

The new pump bracket (PT) made of POM GF30 material simplifies the connection between the standard motor size B3/B14 and the pump head – the entire pump head and pump bracket can be removed by loosening just 4 screws. The pump shaft and ball bearing are integrated into the pump bracket. This makes the pump head very easy to access for servicing, such as cleaning or replacing the flexible impeller, and also makes it easy to replace with another pump head. The pump shaft is made of 1.4404 stainless steel in the standard version. For very demanding applications, the shaft can also be hard chrome-plated or made of duplex, super duplex, or Hastelloy®.

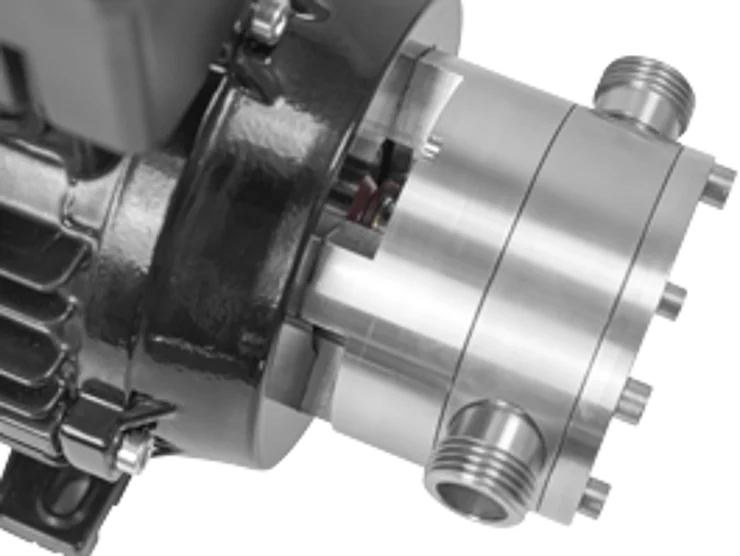

LARGE-SCALE LEAKAGE MILLING - VISUAL INSPECTION OF THE LEAKAGE AREA

In order to detect leaks as quickly as possible, a specially developed pump cover with large milled-out areas is used, which significantly improves visual inspection of the leak chamber and facilitates cleaning. This will ensure even better detection and repair of possible leaks from shafts or mechanical seals in the future and prevent blockages caused by dried-out or crystallized media.

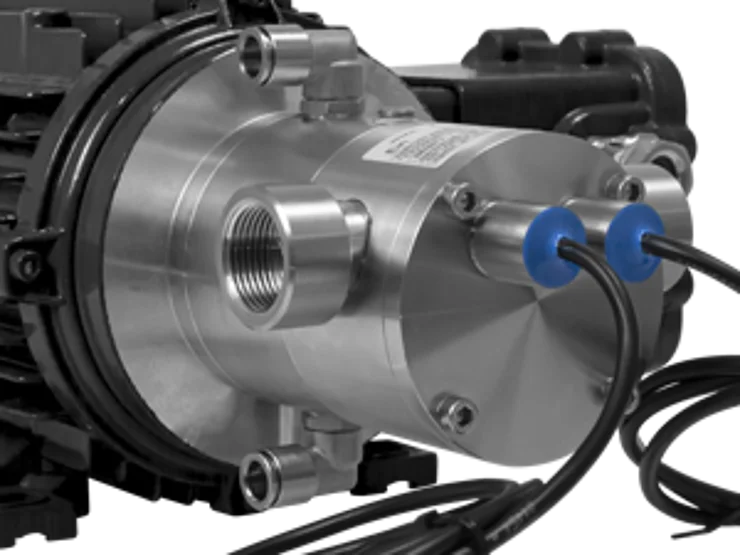

QUENCHING SYSTEMS

Quench systems use negative pressure to move a liquid in a closed circuit into the installation space of the mechanical seal, cleaning it, keeping it moist, and thus preventing dry running. The escaping liquid is removed before it can damage the tightness of the seal by drying out, crystallizing, or sticking.

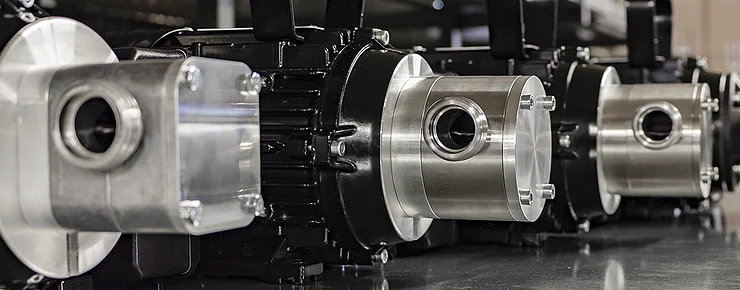

FREQUENCY CONVERTER FOR MOTOR MOUNTING AND WALL MOUNTING

The use of a frequency converter allows the speed to be adjusted to the actual power requirement, which means energy savings in practice, and enables the pump to be operated in both directions. Further settings allow the frequency converter to be programmed according to individual requirements. This programming environment can be used across the entire frequency converter series. For our impeller pumps with 400-volt motors of the UNISTAR 2000 (sizes A, B, and C) and COMBISTAR 2000 (sizes A and B) models, as well as for the NIROSTAR 2000 (sizes A, B, C, D, and E), a wide range of frequency converters is available that are suitable for both motor mounting and wall mounting.

Various coatings

The pump components of ZUWA impeller pumps are made of aluminum and stainless steel. For special applications, these materials can be improved using various processes. Aluminum parts are coated with a corrosion protection layer during the anodizing process, which also provides good wear protection. If a decorative color finish is also desired, the aluminum parts are then further treated. Pump components made of 1.4404 stainless steel can also be hardened. The BORINOX® process achieves a very high level of wear protection, as the surface of the stainless steel becomes at least 5 times harder. Another method of achieving higher wear protection is hard chrome plating. In this process, a chrome coating is applied in layers of 5 μm, which results in surfaces with hardnesses in the range of 68-72 HRC.

NIROSTAR 2000 - NOW AVAILABLE IN ATEX VERSION

We now also offer our proven flexible impeller pump NIROSTAR 2000 with ATEX approval for use in potentially explosive atmospheres. This impeller pump complies with the requirements of category 2G of Directive 2014/34/EU (ATEX class EXii2/2G EX IIB T2 Gb/Gb) both internally and externally and is designed for pumping flammable liquids of explosion group IIB and temperature class T2. This pump can be installed in areas where potentially explosive atmospheres of gases and vapors of explosion group IIB and temperature class T2 may occur. Five impeller types (NBR, EPDM, FKM/FPM, CR, and TPU) are available and can be used for ATEX applications. The sturdy transport trolley also makes this pump very interesting for mobile applications.

ACOSTAR WITH IMPROVED PUMP SHAFT MADE OF HASTELLOY®

Die neue ACOSTAR bietet einiges an Mehrwert. So ist das Pumpengehäuse unserer Impellerpumpe für den Einsatz im chemischen Bereich jetzt über einen aus POM GF30 gefertigten Pumpenträger vom Motor getrennt, welches diesen vor austretenden Flüssigkeiten trennt und schützt und die Wartungs- und Reinigungsarbeiten sehr vereinfacht – mit dem Lösen von nur 4 Schrauben lässt sich der komplette Pumpenkopf samt Pumpenträger demontieren. Die neue Pumpenwelle ist aus dem beständigen Werkstoff Hastelloy® gefertigt. Das Pumpengehäuse ist weiterhin aus PTFE gefertigt, flexible Impellerlaufräder sind in den Materialien Viton® und EPDM verfügbar. Neu hinzugekommen ist ein Adapter, der es ermöglicht, auch die ACOSTAR zukünftig mit Bohrmaschine oder Akkuschrauber zu betreiben.

The new ACOSTAR offers considerable added value. The pump housing of our impeller pump for use in the chemical sector is now separated from the motor by a pump carrier made of POM GF30, which protects it from escaping liquids and greatly simplifies maintenance and cleaning work – the entire pump head and pump carrier can be removed by loosening just 4 screws. The new pump shaft is made of the durable material Hastelloy®. The pump housing is still made of PTFE, and flexible impeller wheels are available in Viton® and EPDM. A new addition is an adapter that will enable the ACOSTAR to be operated with a drill or cordless screwdriver in the future.