For 50 years, the svt Group has been one of Europe's leading full-service providers in the field of preventive fire protection. Products from ZUWA-Zumpe GmbH are also used in this context.

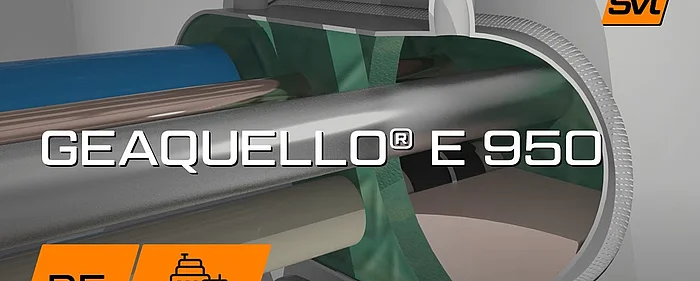

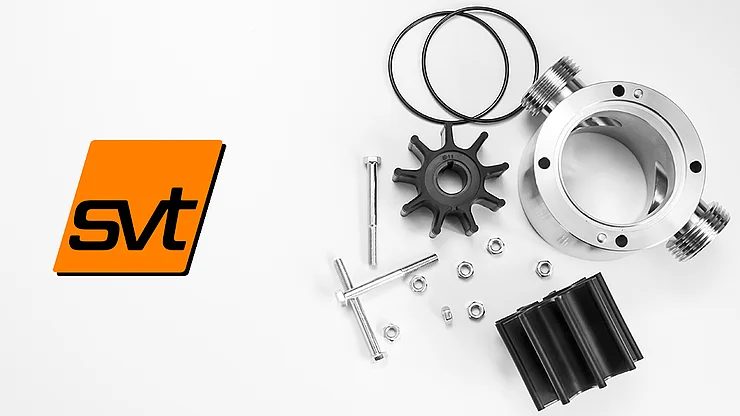

The svt Group relies on the power of ZUWA impeller pumps for the assembly of its new GEAQUELLO® E 950 and GEAQUELLO® CPS grouting systems. The drill pumps impress with their small size, making them ideal for applications on ships and in confined engine rooms. ZUWA drill pumps are dry self-priming and therefore do not require prior filling of the hose and pump body – just right for the rapid delivery of liquids directly from the mixing container. The pumps are operated with a standard cordless screwdriver, enabling quick and easy use.

Im folgenden Video zeigt die svt Unternehmensgruppe den Einbau von GEAQUELLO® E 950 für Schiffe und Offshore-Anwendungen sowie die Verwendung der ZUWA Bohrmaschinenpumpe.

ZUWA drill pumps

- UNISTAR 2001-A / 2001-B

The universal pump with aluminum housing (AlMgSi1) can be used to pump clean or slightly contaminated liquids without abrasive substances, such as heat transfer media, oils, diesel, water, and glycol (coolant).

- COMBISTAR 2001-A / 2001-B

This drill pump is designed for abrasive or slightly corrosive liquids. It is very popular for disposing of waste oil. The pump housing is made of high-quality stainless steel (NIRO 1.4404). The pump cover is made of aluminum.

- NIROSTAR 2001-A / 2001-B

The high-quality drill pump made of stainless steel (NIRO 1.4404) for corrosive media such as chemicals, acids, and alkalis.